Business

Divisions

Our group strives to establish a solid business structure ready to respond flexibly and quickly to any change in the management environment. We seek to earn our customers’ trust and retain satisfaction by expanding our markets and business fields.

Cables mainly made of natural, synthetic rubber, plastics and etc. We have maximized the characteristics of the materials and gained higher trust from costumers.

We are a pioneer of flexible cables and have the top market share in the industry. In order to meet the needs of our customers, we strengthen our sales activities, actively develop new products, improve existing products, enter new business, and expand overseas. We always have a sense of challenger and continue to connect to the next generation.

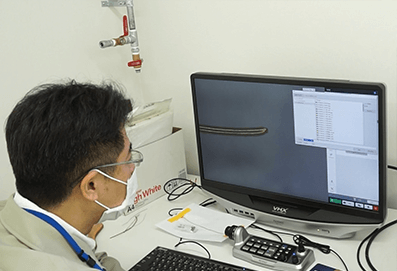

At our factory, we control the quality of each process from raw material to production and shipment. We have established a quality control department to ensure the stable delivery of high-quality products to our customers.

We work on high quality product development, by using our 100 years of experiences, know-how and new values.

We have set up four sales bases and three distribution bases on Japan, and are working hard to provide sales services that are directly connected to our customers and are closely linked to the community. We read costumers needs and provide the best technical proposals and information.

We jointly develop with our customers and deliver plastic products with added value of costumers need. It make us earned a high reputation for good workability and quality products .

We collaborate with our customers on product planning from the conceptualization stage, designing and prototyping.

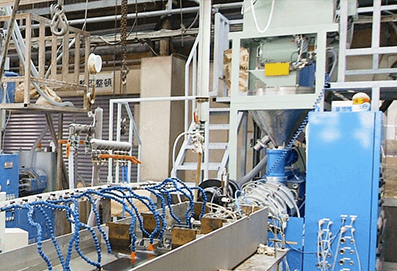

Our manufacturing facilities include CAD, CAM, mold manufacturing equipment, 13 hard lines, 7 soft lines, smelting equipment, inspection equipment, processing lines, and annealing equipment, etc. Our strength lies in our integrated production system that includes not only plastic product design and mold manufacturing, but also processing and assembly.

We develop and produce a series of highly functional tubes and products that meet the needs of our customers, based on our policy of participating in the design and development of products. Depending of costumers requests as chemical resistance, heat resistance, flexibility and other barrier properties.

We position our overseas business as the next pillar of our earnings source, and actively develop the technologies and know-how cultivated at our overseas bases to contribute to regional and industrial development.

The International Business Division is actively recruiting foreign employees. Currently, we have employees from Indonesia, Vietnam, and are promoting globalization with language capabilities in English, Tagalog, Vietnamese, and Indonesian.

In 2007, MITSUBOSHI PHILIPPINES CORPORATION (MPC), the first overseas base was established in the Philippines. At the time of our founding, we mainly manufacture secondary processed products of Polymatech products. Production of plastic electric wires started in 2010. Currently (as of 2020), we have 2 Japanese managers and 60 local staffs.

A new rubber cable line was inaugurated on November 2018. The quality of Philippines products is the same as our Japan factory. We thoroughly manufacture and sell our products locally, and in accordance with JIS standards.

We manufacture our products in our overseas bases with the cooperation of our OEM factories (China / Taiwan). In the Polymer Tech business as well, we are proactively responding to orders from overseas direct customers, and have built an immediate delivery system.

Our company handles electric heating alloy wires/belts and resistance wires/belts not only for home appliances that are indispensable to our lives, but also for industrial furnaces, food furnaces, fittings such as gas pipes that are essential for infrastructure, and various industrial equipment. Also, it is widely used in various fields such as automotive applications such as seat heaters and resistor applications.

(1) We can also handle severe conductor resistance tolerances. (Achievement of ±1.0%

(2) Reliable quality control system and environmental support (ISO9001, 14001 certification acquired)

(3) Support for various development projects (Small-scale trial production is possible)

(4) Extra-fine wire can be manufactured up to φ0.02. )

Nickel chrome, iron chrome, pure nickel, copper manganese, copper nickel, iron nickel, molybdenum

It is used for industrial heaters, home appliance heaters, resistors, car seat heaters, toilet seat heaters, EF joints, heat-resistant wire mesh, antifreeze road heaters, battery components, etc.

We develop and sell energy-saving products, including Retro fit LED Lamps.

We provide power generation systems using solar panels.

Creation, Conservation, and Storage of Energy as Our New Pillars

We challenge new markets with excellent supply chains and high development capabilities.